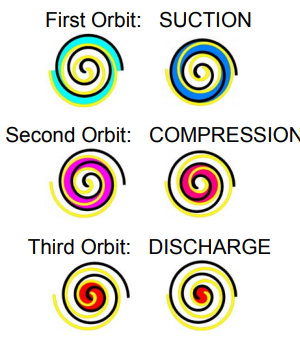

First orbit; SUCTION gas enters at the perimeter of the scroll elements and is

sealed as the scrolls rotate approximately one revolution.

Second orbit; During the COMPRESSION process, the gas is further compressed towards the center of the scroll elements to an intermediate

pressure.

Third orbit; In the DISCHARGE orbit, the gas is further compressed to

discharge pressure and then exits at the center through the discharge port.

With a three step simultaneous process of suction, compression and

discharge and two gas pockets in each step that are 180 degrees apart, the

compression process is balanced and very smooth, resulting in high efficiency,

low sound/vibration and excellent reliability.

- Sound sources are minimized – The SANYO scroll has a fixed

eccentric offset, completely eliminating scroll contact in the radial

direction, and the noise generated from radial scroll contact. Axial

sealing is accomplished with PPS resin tip seals that are

significantly quieter than the cast iron used on other scrolls. - Transmission through the shell is significantly reduced – With

thicker center shell, structural discharge baffle, optimized top shell

design and heavy duty seam and location welds. - The resulting overall sound level is 5-8 dB(A) lower than the

competition on a weighted average basis.

- Initial compressor design from Japan, supported by Abusive

Reliability Testing at Dalian to monitor factory process. - Rigorous customer application approval process assures reliable

system designs. - First year reliability < 0.08%